No products in the cart.

Lightray

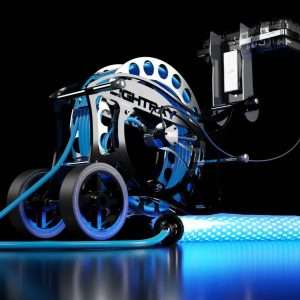

LightRay’s UV casting systems bring precision, speed, and simplicity to trenchless pipe installations. From spot repairs on a section of pipe to completion of a full lateral inversion, LightRay’s patented LED UV technology ensures high-quality results with fast casting times, flexible navigation, and unmatched control — all made and supported in the USA.

Uses & Benefits

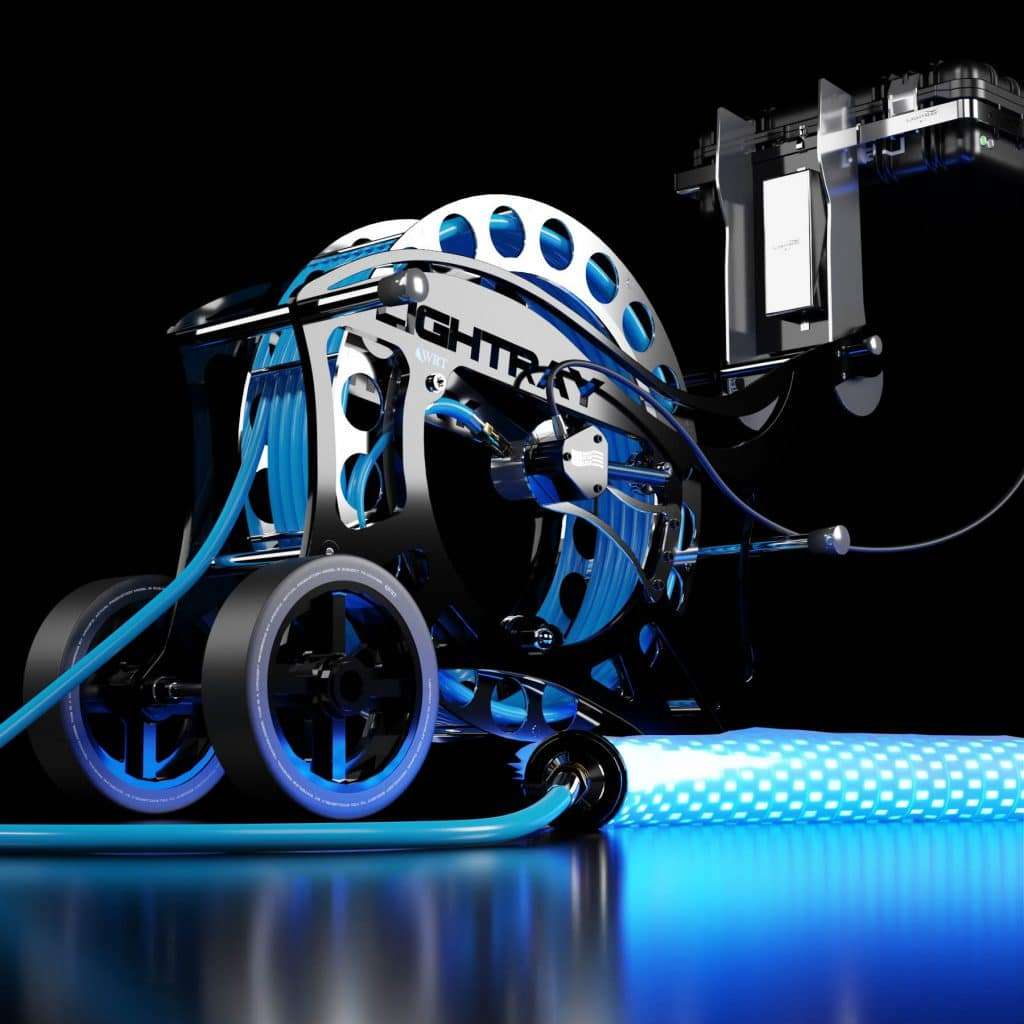

LightRay LR3 Spot Repair System

The LR3 is the most advanced UV cast-in-place pipe technology that gives the operator complete control of the curing process. It is engineered for targeted repairs in pipe diameters ranging from 3” to 12”. The system can significantly reduce costs and risks when compared to traditional thermo-setting or ambient-cured CIPP liners. It’s perfect for municipal contractors and plumbers who want to reduce curing time, increase efficiency, and maintain full control of the process on every job.

- Enables same-day repairs

- Pipe can be back in service within an hour

- Reduced manpower for job completion

- Increased profitability

- Casting times as low as 5 minutes

- Liner materials come ready to install

- Easily navigates 45° and 90° bends

- Training included with every system

- Backed by 24/7 technical support

- Made in the USA

LightRay LRI Lateral Inversion System

The LRI is the most advanced system in the UV cast inversion liner market. It is designed for small-diameter lateral relining and blends familiar inversion techniques with advanced UV curing control. The simple system gives the operator complete control over the process and very closely resembles traditional ambient cure inversion methods.

- No complex parts or computer-regulated movement

- Cures up to 150 ft of liner at 6.3 ft/min in all types of pipe

- Uses a 50-ft cold LED light train for industry-leading cure times and consistent results

- No heat required — cures without elevated temperatures

- Handles multiple 90° bends with ease

- Liners arrive pre-wet out, ready to install, and can be stored for up to 9 months

- ASTM F1216 compliant

- Training included with every system

- Backed by 24/7 technical support

- Made in the USA

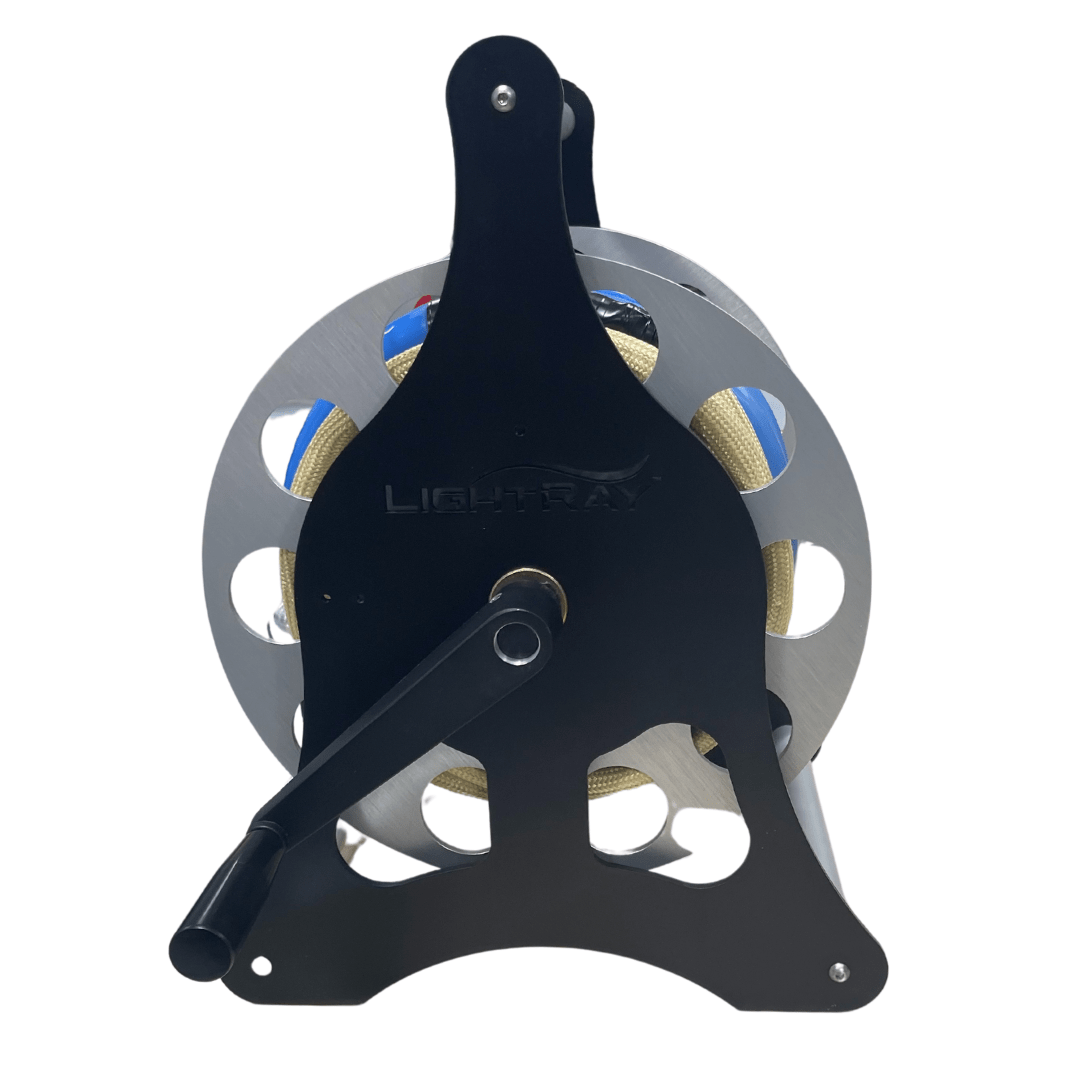

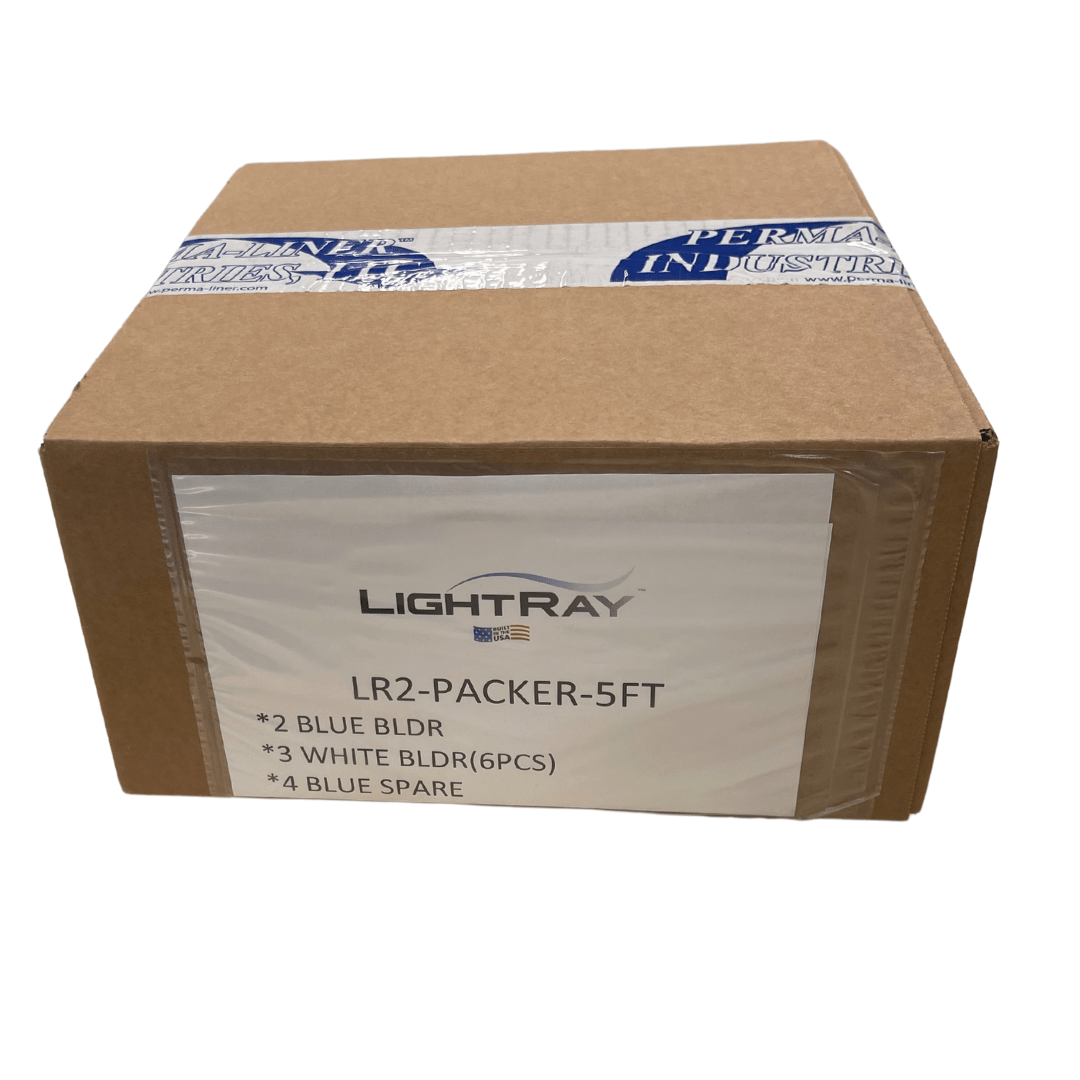

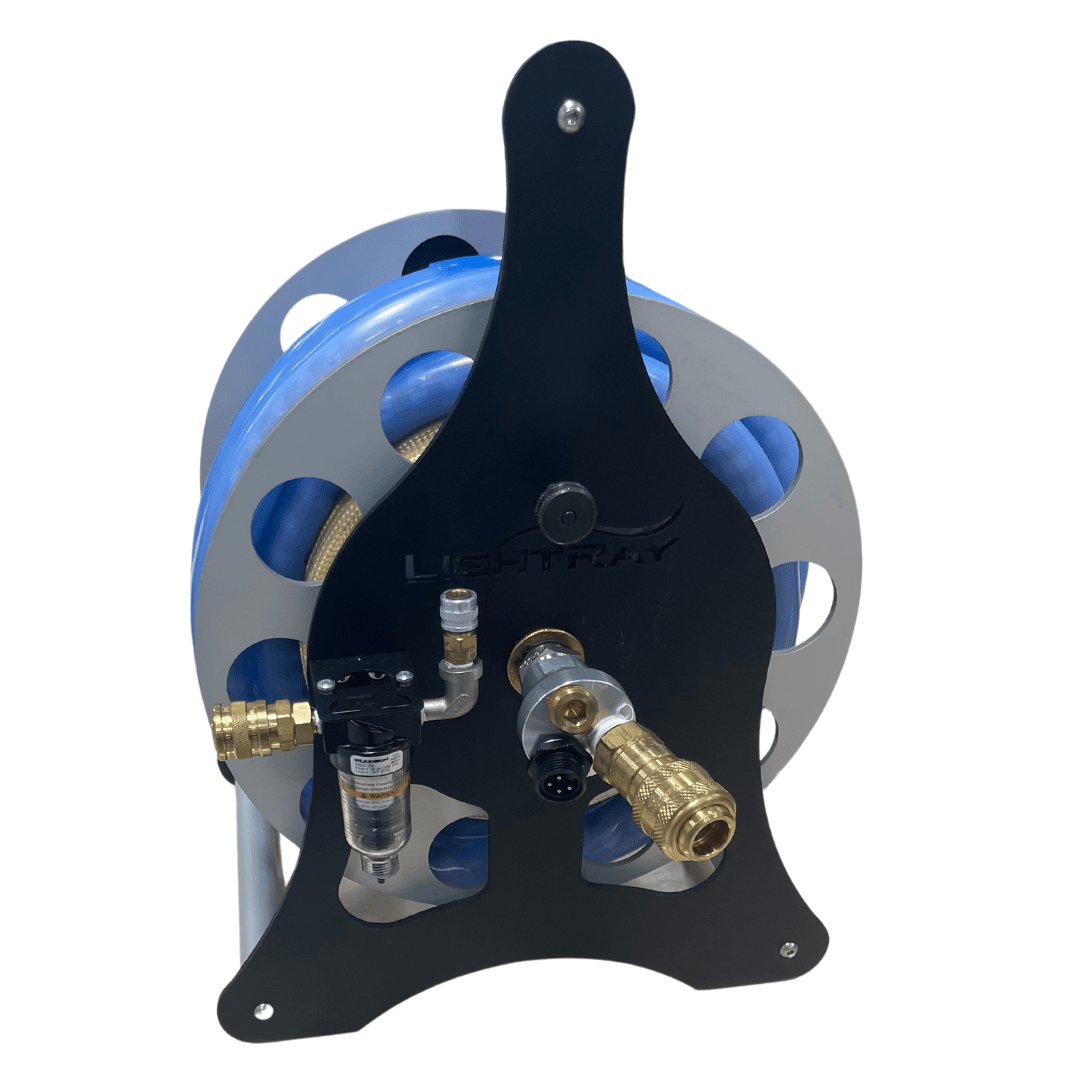

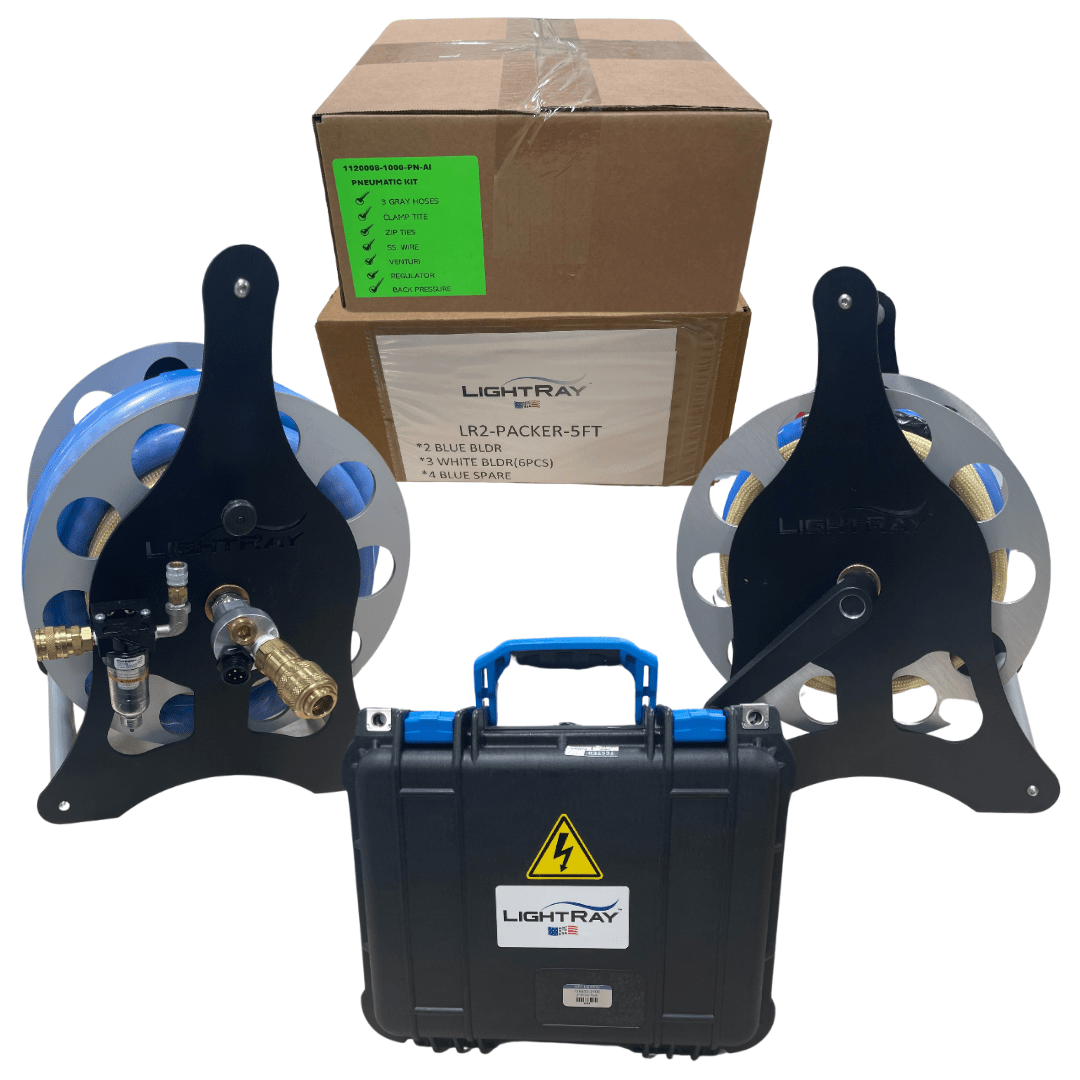

LightRay LR2 Pull-in-Place System

The LR2 is a compact, 2” LED UV casting system designed for pull-in-place pipe repairs in tight, hard-toaccess areas. It is ideal for municipal infrastructure, industrial drainage networks, home plumbing, and heritage sites. The system combines speed, simplicity, and safety in a small, maneuverable footprint.

• Designed specifically for 2” pipe diameter

• Pull-in-place application with simple setup

• Casting times as low as 5 minutes

• Perfect for interior pipes and limited access conditions

• Comprehensive package includes everything needed for the repair

• Packer available in both 5-ft and 20-ft lengths, equipped with a reel and 100-ft hose

• Training included with every system

• Backed by 24/7 technical support

• Made in the USA

Technical Specifications

Technical Specifications

| Feature | LR3 | LRI |

| Pipe Sizes | 3", 4", 6", 8", 9" (Pittsburgh), 10", 12" | 3", 4", 6", including transitional flex |

| Reel Hose/Light Train Length | 100 ft or 150 ft reel hose with 5, 10, or 20 ft packer | 50 ft light train |

| Cast Time | ~5-10 minutes | ~6.3 ft/min |

| Bends | Navigates 45° & 90° bends | Navigates multiple 90° bends |

| Warranty | 1-Year Limited | 1-Year Limited |

Images & Videos

Downloads

How to Use

Ready to Learn More?

Looking for a faster, more cost-efficient way to complete CIPP jobs? Contact us today at 724-393-0383 or info@in-linerenewalsolutions.com to schedule a demo, get a quote, or speak with an expert about LightRay!

Hear What Our Customers Say About Our Products

The Trenchless Equipment Provider Trusted by Contractors

Sign up for our newsletter

Be the first to know about the latest advancements in trenchless equipment technology