No products in the cart.

Picote Millers

Picote’s line of high-speed Millers provides industry-leading performance for cleaning, cutting, reinstatement, and coating. Each Miller is engineered for specific pipe diameters and applications — from small-diameter descaling to heavy-duty concrete removal — making them essential tools for trenchless professionals who seek reliability and power in the field.

Uses & Benefits

Mini Miller

The Mini Miller is a high-speed, high-torque machine for cleaning, descaling, and removing roots in smaller pipes.

- Descaling

- Root Cutting

- Reinstatements

- Unblocking

- Brush Coating

- Trimming Back Overshot CIPP Lining

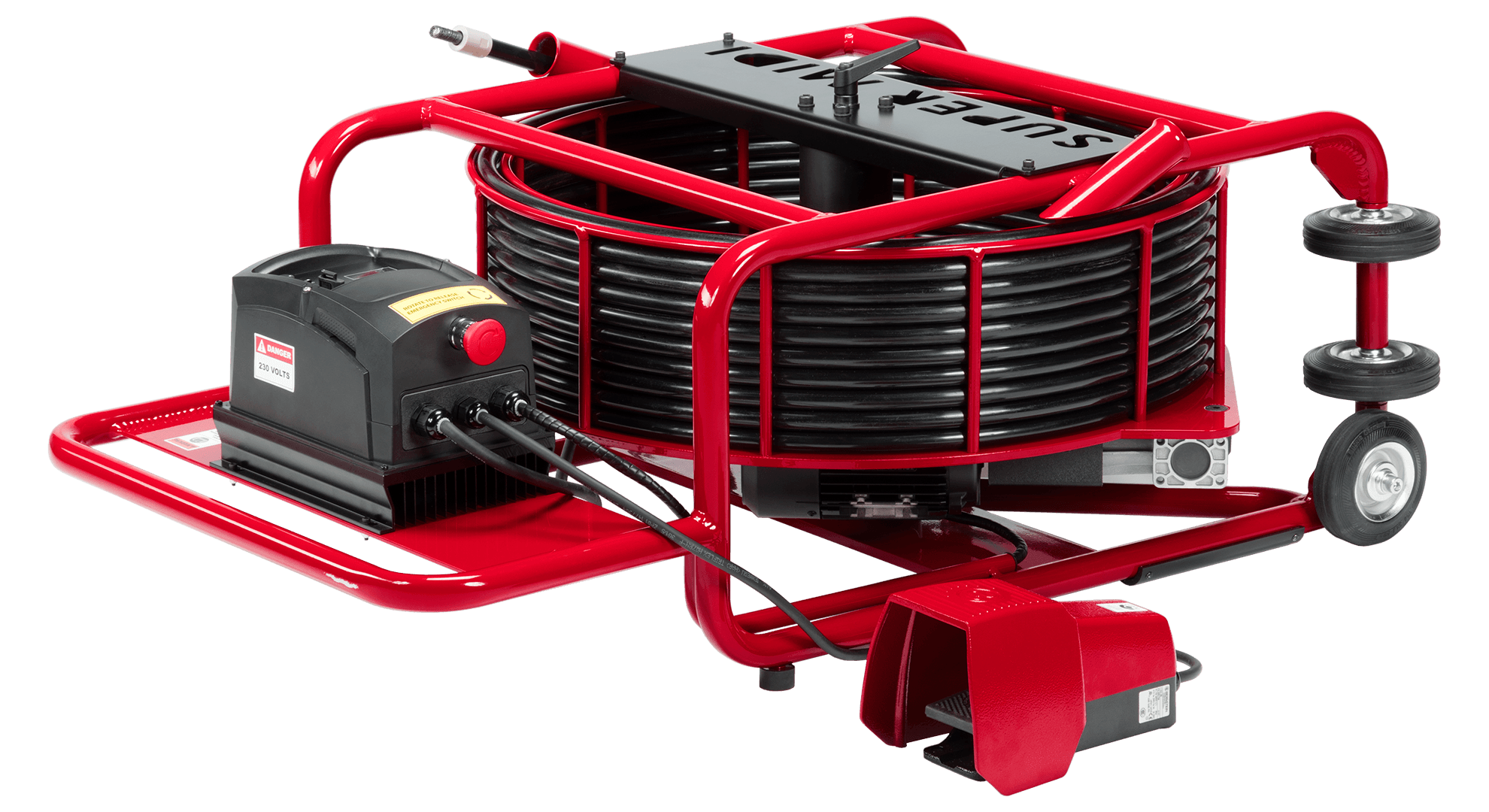

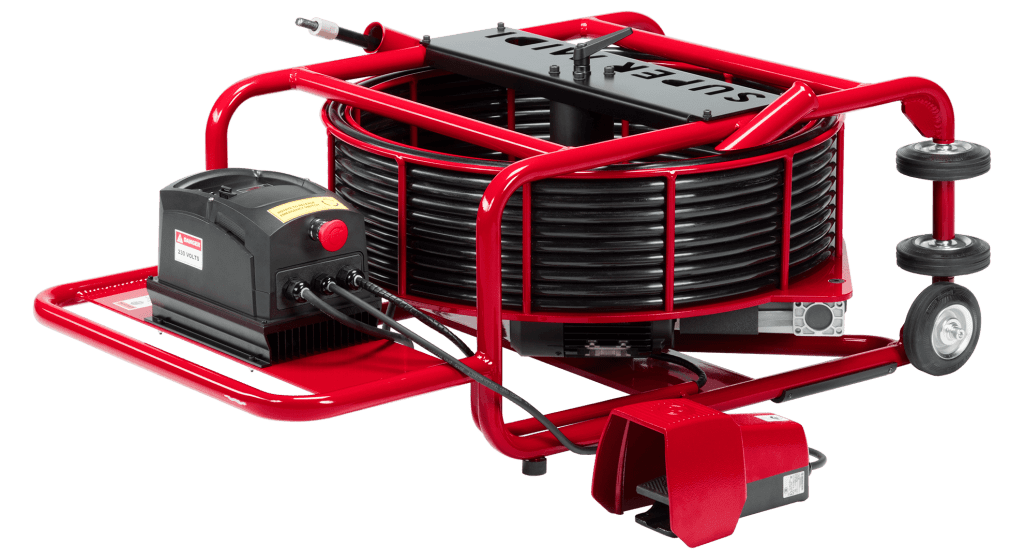

Super Midi Miller

The Super Midi is designed for high-speed cleaning with a range of specialized Cleaning Chains — excellent for unblocking and removing roots, as well as reinstating CIPP connections.

- Descaling

- Root Cutting

- Reinstatements

- Unblocking

- Brush Coating

- Removing Failed Patches

- Cutting Out Intruding Connections

- Removing Metal Rebar

- Removing Grout

- Trimming Back Overshot CIPP Lining

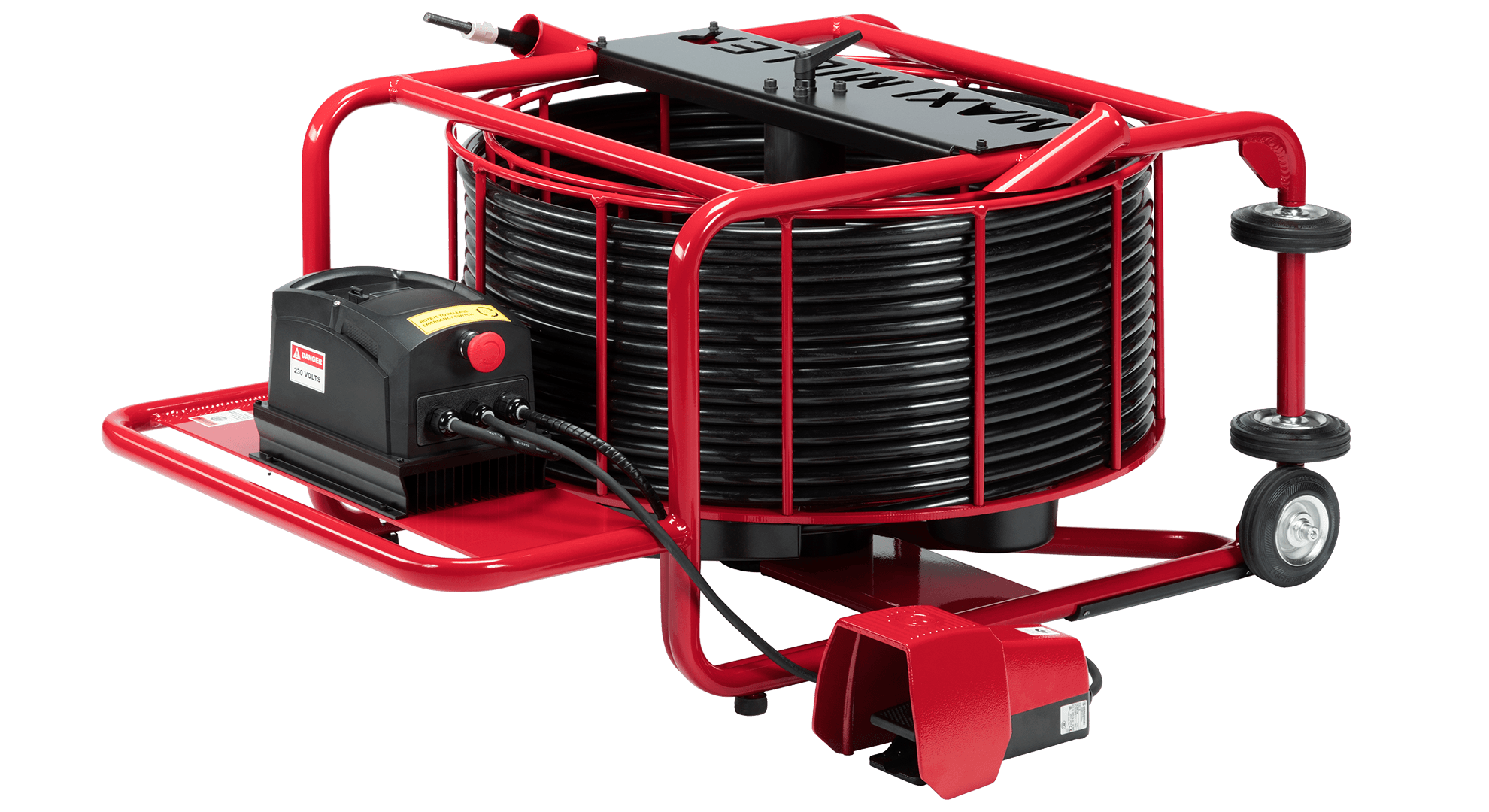

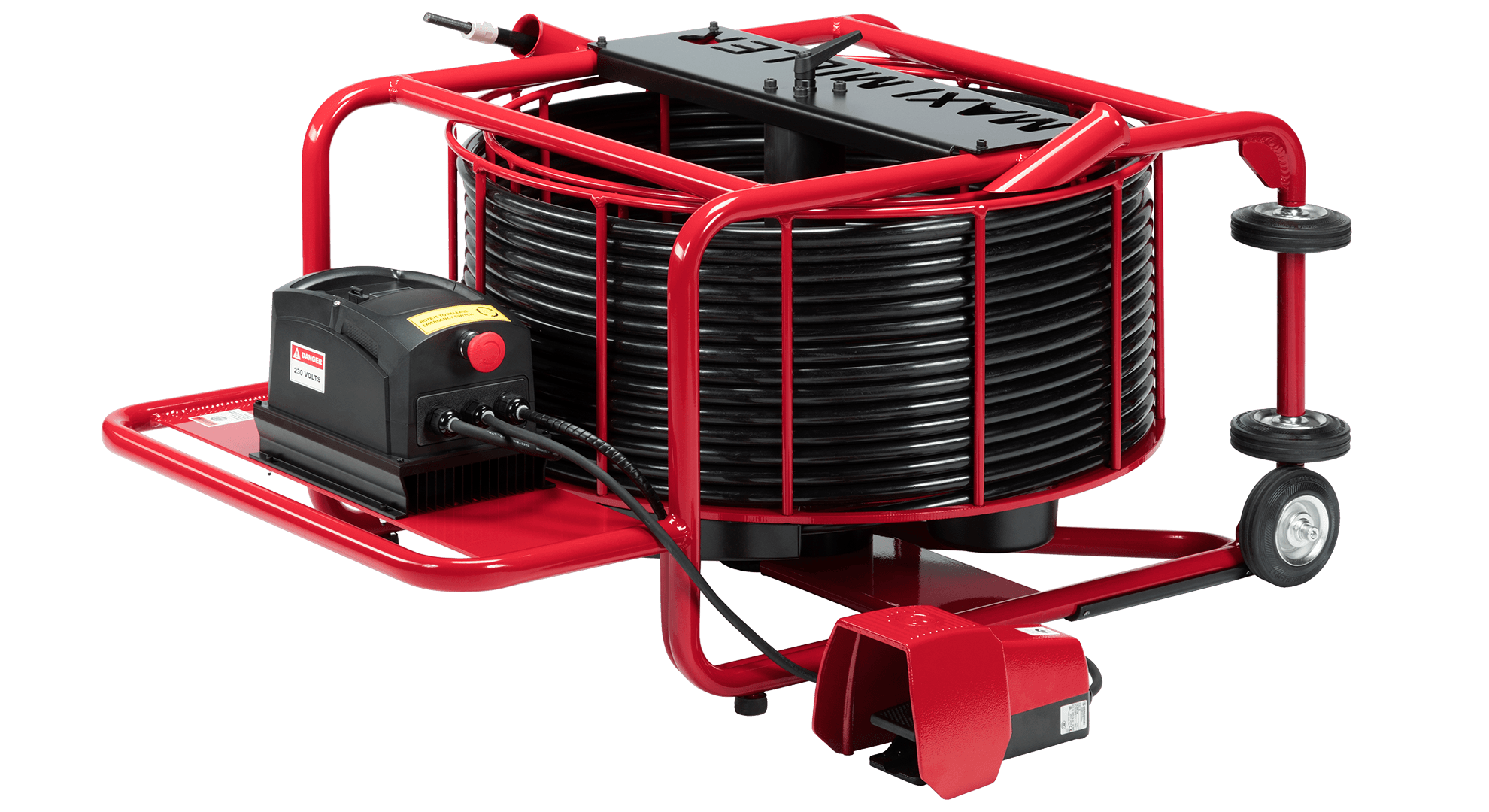

Maxi Miller

The Maxi Miller is designed for tough challenges like heavy scale build-up and roots. Remove concrete or failed CIPP linings with a specialized Twister and Cleaning Chains, FOGs (fats, oil & grease) with the Smart Spider, perform reinstatements with one of a range of custom cutters, or expand your business further and team with the Maxi Coating Pump for the Picote Brush Coating™ System.

- Descaling

- Root Cutting

- Reinstatements

- Brush Coating

- Concrete & Grout Removal

- Removing Metal Rebar

- Removing Intruding Connections & Displaced Joints

- Removing Failed Patches & Failed or Collapsed CIPP Linings

- Removing Foreign Objects

- Trimming Back Overshot CIPP Lining

- Specialized Cleaning

Features of All Picote Millers

- High-torque motors with variable RPM control

- Lightweight aluminum frames for easy transport

- Safety-first features, including operator foot controls, shaft casing protection, and emergency stop switches

- Compatibility with Picote’s extensive line of accessories

Technical Specifications

Technical Specifications

| Model | Pipe Range | Range | Weight | RPM Range | Output | Coating Compatible |

| Mini Miller | 2"–4" (DN50–100) – Cleaning/Descaling; 2"–3" (DN50–75) – Cutting/Reinstatement; 2"–6" (DN50–150) – Picote Brush Coating™ |

16m (50ft) + 10m (32ft) extension |

60 lbs (27kg) | 500–2900 RPM | 1100W | Mini Pump/Xpress |

| Super Midi | 3"–6" (DN70–150) – Cleaning/Descaling; 3"–6" (DN70–150) – Cutting/Reinstatement; 3"–8" (DN70–200) – Picote Brush Coating™ | 20m (65ft) + 10m (32ft) extension

|

152 lbs (69kg) | 500–1500 RPM | 1.5kW | Maxi Pump/Xpress |

| Maxi Miller | 3"–10" (DN70–250) or DN250 (10”) with 240V Version – Cleaning/Descaling; 3"–8" (DN70–200) – Cutting/Reinstatement; 3"–12" (DN70–300) – Picote Brush Coating™ | 30m (100ft) + 15m (50ft) or 10m (32ft) extension depending on version

|

196 lbs (89kg) | 500–1475 RPM | 1.13kW | Maxi Pump/Xpress |

Images & Videos

Downloads

How to Use

Ready to Learn More?

Whether you’re upgrading your cleaning power, tackling major reinstatement projects, or expanding into coating, there’s a Picote Miller built for your needs. Contact us today at 724-393-0383 or info@in-linerenewalsolutions.com to schedule a demo, get a quote, or speak with an expert!

Hear What Our Customers Say About Our Products

The Trenchless Equipment Provider Trusted by Contractors

Sign up for our newsletter

Be the first to know about the latest advancements in trenchless equipment technology